Product Description:

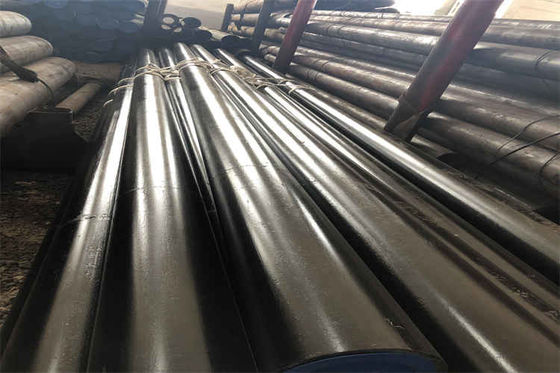

Our seamless pipes are meticulously crafted from high-quality materials, offering a superior solution for various industrial applications. Designed with precision and expertise, our seamless pipes provide exceptional strength, durability, and reliability.

The seamless construction of our pipes ensures a smooth and uninterrupted inner surface, free from any welds or joints. This design eliminates weak points and potential leakage, resulting in enhanced performance and increased safety.

Crafted with advanced manufacturing techniques, our seamless pipes exhibit excellent dimensional accuracy, ensuring a precise fit and optimal functionality. They are available in a wide range of sizes, diameters, and thicknesses to suit diverse project requirements.

Our seamless pipes are manufactured from premium-grade materials, carefully selected for their exceptional mechanical properties and corrosion resistance. This allows them to withstand extreme conditions, including high temperatures, pressure, and corrosive environments.

Choose our seamless pipes for their impeccable craftsmanship, exceptional performance, and versatility. Whether it's for critical applications or everyday use, our seamless pipes deliver the strength, durability, and reliability you can depend on.

Features:

Advantages of Seamless Pipes

Seamless pipes are known for their many incredible benefits. For example:

- Seamless construction: Seamless pipes are manufactured without any welding or joints along their length. This makes for a smooth inner surface that eliminates weak points and the risk of leaks or failure.

- Superior strength:Thanks to their lack of welds or joints, seamless pipes have excellent strength and structural integrity that allows them to bear heavy loads and resist high pressure.

- Enhanced corrosion resistance: These pipes are commonly made from corrosion-resistant materials, such as stainless steel or alloy steel, thus protecting them from the effects of moisture, chemicals, and harsh environments.

- Precise dimensional accuracy:Seamless pipes are manufactured with high precision, resulting in consistent and accurate dimensions. This allows for a tight fit and compatibility with various components.

Technical Parameters:

Seamless pipes are available in a range of diameters, typically measured in inches or millimeters. This diameter determines the size of the pipe and its compatibility with fittings and connections.

The wall thickness of a seamless pipe refers to the thickness of the pipe's cylindrical wall. It is measured in inches or millimeters and determines the pipe's strength and pressure rating.

Seamless pipes come in different lengths, typically measured in feet or meters. Common lengths include 20 feet (6 meters) and 40 feet (12 meters), while longer or shorter lengths may be available depending on specific requirements.

Seamless pipes can be manufactured from different materials, such as carbon steel, stainless steel, alloy steel, or other specialized alloys. This material grade indicates the composition and properties of the pipe, including its corrosion resistance, temperature resistance, and mechanical strength.

Applications:

The oil and gas industry is highly dependant on seamless pipes for exploration, production, and transportation of oil, gas, and petroleum products. These pipes are used in pipelines, offshore platforms, refineries, and petrochemical plants.

The chemical and petrochemical industry also heavily relies on seamless pipes for efficiently transporting corrosive chemicals, acids, and gases. These pipes are utilized in chemical processing plants, fertilizer manufacturing, and storage facilities.

Finally, seamless pipes are indispensible in power plants for various applications. From steam systems and boiler tubes, to heat exchangers and high-pressure piping, these pipes make efficient power generation from fossil fuels and renewable energy sources possible.

Support and Services:

We provide technical support and services for Seamless Steel Pipe. Our services include:

- Installation and on-site support

- Maintenance and repair

- Product upgrades and enhancement

- Troubleshooting and diagnostics

- Performance optimization

- Spare parts supply

We are committed to providing quality service and support, so you can be confident that your Seamless Steel Pipe will be running smoothly and efficiently.

Packing and Shipping:

Packaging and Shipping for Seamless Steel Pipe:

Seamless steel pipes are packaged in bundles or in wooden boxes, depending on the size of the pipes. For pipes that are too large to fit in a bundle, they are wrapped with reinforced plastic bands to prevent any damage during the shipping process. The wooden boxes are typically lined with foam and other protective materials to ensure the pipes arrive in perfect condition.

The pipes are then shipped via sea freight or air freight depending on the customer’s needs. When shipped via sea freight, it is important to ensure the pipes are properly secured and the wooden boxes are sealed with waterproof tape. When shipped via air freight, the pipes are typically wrapped in a protective foil to ensure no damage is done during the flight.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!