Product Description:

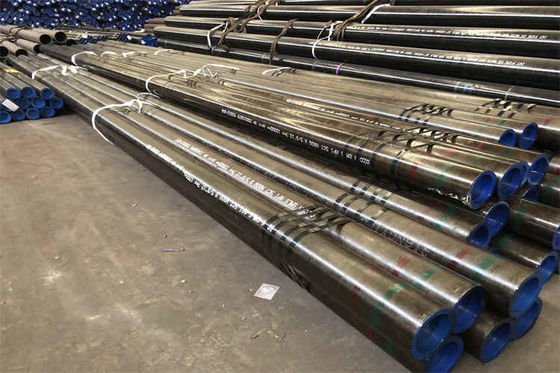

Seamless Steel Pipes: Exceptional Strength and Durability

Seamless steel pipes are widely recognized for their exceptional strength and durability. Due to their seamless construction, they can withstand high levels of pressure, temperature, and mechanical stresses, making them highly suitable for demanding applications.

Uniformity in Structure and Strength

One of the key advantages of seamless steel pipes is the absence of welded joints or seams. This ensures uniformity in their structure and strength along the entire length of the pipe. As a result, these pipes have enhanced reliability and performance, making them a preferred choice in various industries.

Efficient Fluid Flow with Reduced Resistance

The smooth and seamless interior surface of these pipes allows for efficient fluid flow with reduced frictional resistance. This property is particularly important in applications involving the transportation of liquids or gases. The seamless design eliminates any obstacles or irregularities in the flow, resulting in a more efficient and reliable transportation process.

Versatile Corrosion Resistance Options

Seamless steel pipes can be manufactured from a variety of corrosion-resistant materials such as carbon steel, stainless steel, or alloy steel. This allows for the selection of a suitable material based on the specific corrosion resistance requirements of the application. It ensures that the pipes can withstand harsh environments and corrosive substances, making them a durable and long-lasting solution.

Features:

Seamless Construction

Seamless steel pipes are produced without any welded joints or seams. They are created from a single, solid piece of steel, resulting in a continuous and uninterrupted structure along the entire length of the pipe.

Superior Strength

Known for their exceptional strength and durability, seamless steel pipes are able to withstand high levels of pressure, temperature, and mechanical stress. This makes them well-suited for use in demanding applications.

Uniformity

The absence of welded joints or seams in seamless steel pipes ensures a consistent structure and strength. This uniformity enhances the reliability and performance of the pipes, reducing the risk of failure.

Technical Parameters:

Dimensions:

Seamless steel pipes have precise measurements that determine their size and shape. This includes the outer diameter (OD), wall thickness (WT), and length. These dimensions are typically specified in millimeters (mm) or inches (in).

Material:

Seamless steel pipes can be made from a variety of materials, such as carbon steel, stainless steel, alloy steel, or other specialized alloys. The choice of material depends on the specific needs of the application, including strength, corrosion resistance, and temperature resistance.

Tolerances:

Tolerances refer to the acceptable deviation from the specified dimensions. This includes tolerances for outer diameter, wall thickness, and length. Tolerances ensure that the pipes meet the required standards and specifications.

Surface Finish:

The surface finish of seamless steel pipes can vary based on the manufacturing process and intended use. Common surface finishes include mill finish (as-rolled or as-drawn), pickled and oiled, or polished. The surface finish can affect the overall appearance, corrosion resistance, and functionality of the pipes.

Applications:

Uses of Seamless Steel Pipes

The oil and gas industry extensively relies on seamless steel pipes for the transportation of fluids, including crude oil, natural gas, and refined petroleum products. These pipes are well suited for both onshore and offshore applications, as they can withstand high pressures and temperatures.

Petrochemical plants also utilize seamless steel pipes for conveying various chemicals and gases. These pipes are highly resistant to corrosion and can handle aggressive substances, making them an essential material in this industry.

In power generation, seamless steel pipes are used for the transport of steam, water, and other fluids in boilers, heat exchangers, and condensers. They are also crucial for the transportation of high-pressure steam in turbine systems. Their strength and durability make them a reliable choice for this industry.

The automotive industry relies on seamless steel pipes for various components and systems, such as fuel injection, exhaust, and air conditioning. These pipes are lightweight, easy to fabricate, and have excellent corrosion resistance, making them a vital material for the production of automobiles.

In the construction industry, seamless steel pipes are commonly used for structural applications, including building frameworks, beams, and columns. They are also utilized for plumbing and gas distribution systems. Their versatility and strength make them a popular choice in the construction industry.

Customization:

Customized Services for Seamless Steel Pipe

Brand Name: Seamless Steel Pipe

Place of Origin: China

Certification: BV, SGS, ABS

Minimum Order Quantity: 1TON

Price: USD600-1500/TON

Packaging Details: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Delivery Time: 5-7 working days

Payment Terms: T/T, L/C

Supply Ability: 10000 tons/year

Port: Tianjin/Shanghai

Processing: Welding, Cutting

Wall Thickness: 2mm - 60mm

Packing: In Bundles, In Bulk, Or According To Customers' Requirements

Pipe Type: SMLS

Customized Services for Seamless Steel Pipe include:

- Customized length and diameter of seamless stainless steel tubing

- Customized specifications and standards according to ASTM A519

- Customized packaging options for seamless tubes and pipes

- Customized delivery time and payment terms

- Customized supply ability to meet customer's demand

- Customized port for shipment

- Customized processing services such as welding and cutting

- Customized wall thickness options

- Customized packing methods according to customer's requirements

- Customized type of seamless pipe according to customer's needs

Packing and Shipping:

Packaging and Shipping for Seamless Steel Pipe

At our company, we take great care in packaging and shipping our seamless steel pipes to ensure their safe delivery to our customers. Here is a breakdown of our packaging and shipping process:

With our meticulous packaging and reliable shipping methods, you can trust us to deliver your seamless steel pipes safely and efficiently. Contact us today for more information or to place an order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!