Product Description:

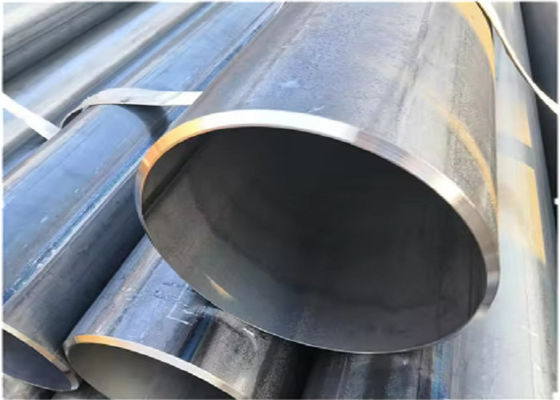

The ERW Steel Pipe is a premium product that exemplifies engineering excellence, precision manufacturing, and superior material quality. ERW, which stands for Electric-Resistance-Welded, signifies a manufacturing process where the steel pipe is welded using heat generated from electric resistance. This method ensures a strong, seamless weld and is particularly suitable for high-pressure applications. Our ERW Steel Pipes come with a comprehensive range of specifications to meet the diverse needs of various industries.

The wall thickness of our ERW Steel Pipe ranges from 1.8mm to 22.2mm, allowing for a versatile application in industries such as construction, automotive, and petrochemical. This range of wall thickness also ensures that the pipe can handle different pressures and loads, making it a reliable choice for both above-ground and underground installations.

Length is another critical factor in the utility of steel pipes. Our pipes are available in lengths from 5.8m to 12m, catering to the varying requirements of our clients. Whether it is for long stretches of pipeline or tailored segments, our ERW Steel Pipes can be supplied to fit specific project demands without compromising on quality or performance.

Attention to detail is evident in the ends type of our ERW Steel Pipes. Clients can choose from Plain End, Beveled End, or Threaded configurations, offering flexibility for different connection methods. The Plain End is ideal for butt welding, the Beveled End prepares the pipe for a more secure weld, and the Threaded option provides a robust screw-in assembly. These end types are carefully crafted to ensure a seamless and secure integration into any piping system.

Quality assurance is paramount in our production process, and our ERW Steel Pipes come with the ISO 9001 certification, demonstrating our commitment to international quality standards. Additionally, the API certification ensures that our pipes meet the American Petroleum Institute's stringent requirements for oil and natural gas industries. These certifications reflect our dedication to providing products that our customers can trust for their critical operations.

The material composition of our ERW Steel Pipes is equally diverse. We offer pipes made from Carbon Steel, Stainless Steel, and Alloy Steel, each selected for its unique properties and benefits. Carbon Steel is known for its strength and durability, making it ideal for general purpose applications. Stainless Steel provides excellent corrosion resistance, suitable for harsh environments, while Alloy Steel is sought after for its enhanced mechanical properties and heat resistance, perfect for demanding industrial uses.

For those in need of specialized pipes, our Double-Submerged-Arc Welded Steel Pipe variant offers a robust solution. The double-submerged-arc welding process provides even stronger welds by utilizing two arcs, making these pipes an excellent choice for heavy-duty applications that require a high degree of structural integrity.

Overall, the ERW Steel Pipe stands as a testament to advanced manufacturing and material science. It offers a combination of strength, precision, and reliability, meeting the stringent requirements of various industries. With the flexibility of wall thicknesses, lengths, end types, and materials, along with the assurance of quality certifications, our ERW Steel Pipes are the go-to choice for professionals seeking superior piping solutions.

Features:

- Product Name: ERW Steel Pipe

- Material: Carbon Steel, Stainless Steel, Alloy Steel

- Outer Diameter: 21.3mm-660mm

- Surface Treatment: Black Painting, Galvanized, Anti-Corrosion Coating

- Package: Bundles, Seaworthy Wooden Cases, Wooden Pallet

- High-Frequency Welded Steel Pipe

- Electric-Resistance-Welded Steel Pipe

- Longitudinal-Seam Welded Steel Pipe

Technical Parameters:

| Parameter |

Description |

| Product Name |

ERW Steel Pipe |

| Wall Thickness |

1.8mm-22.2mm |

| Outer Diameter |

21.3mm-660mm |

| Length |

5.8m-12m |

| Material |

Carbon Steel, Stainless Steel, Alloy Steel |

| Surface Treatment |

Black Painting, Galvanized, Anti-Corrosion Coating |

| Ends Type |

Plain End, Beveled End, Threaded |

| Application |

Oil And Gas Industry, Water Supply And Plumbing, Structural And Construction |

| Package |

Bundles, Seaworthy Wooden Cases, Wooden Pallet |

| Certificate |

ISO 9001, API |

Applications:

The ERW Steel Pipe, standing for Electric-Resistance-Welded Steel Pipe, is a product of excellence and precision with its origins in China. This high-quality steel pipe is manufactured under the stringent quality standards such as ASTM, ISO, and EN, ensuring that the product meets international criteria for safety and reliability. The ERW Steel Pipe brand boasts not only a high certification standard but also a substantial supply ability of 10000 tons/year, making it a reliable choice for large scale projects and industries.

With a minimum order quantity of just 1 TON and a competitive price range of USD600-1500/TONS, the ERW Steel Pipe provides an accessible solution for various applications while ensuring cost-effectiveness. Clients can expect their orders to be meticulously packaged in bundles, with plastic or steel caps, and if necessary, in wooden cases or pallets to ensure the product's integrity during transportation. Additionally, the ERW Steel Pipe comes with a swift delivery time of 15-25 days, allowing for prompt project initiation.

Payment for the ERW Steel Pipe is facilitated through flexible terms, accepting both L/C and T/T, which provides purchasers with the convenience to choose the method that best suits their financial processes. With a range of outer diameters from 21.3mm to 660mm, this product can accommodate diverse industry requirements. The material composition includes not just Carbon Steel but also Stainless Steel and Alloy Steel, catering to various strength and corrosion resistance needs. The ERW Steel Pipe comes in different ends types such as Plain End, Beveled End, and Threaded, offering versatility for different connection methods in installation.

The ERW Steel Pipe is suitable for a wide array of occasions and scenarios, including but not limited to oil and gas line pipes, structural application, and construction projects. The product adheres to standards such as ASTM A53, ASTM A500, API 5L, EN10219, and EN10210, which speaks to its adaptability and suitability for different environmental conditions and pressures. The High-Frequency Induction Welded Steel Pipe aspect of the ERW Steel Pipe refers to the technology used in its manufacturing, ensuring a strong, durable weld that can withstand high pressures and temperatures.

With the ISO 9001 and API certificates, customers are assured of the ERW Steel Pipe's quality and reliability. Its application is broad, ranging from plumbing and heating to more industrious uses such as oil and gas pipelines. The Electric-Resistance-Welded Steel Pipe is not just a product; it is a guarantee of strength, durability, and excellence, perfectly suited to meet the demands of modern engineering and construction.

Customization:

Brand Name: ERW Steel Pipe

Place of Origin: China

Certification: ASTM, ISO, EN

Minimum Order Quantity: 1 TON

Price: USD600-1500/TONS

Packaging Details: Bundles, Plastic or Steel Caps, Wooden Cases or Pallets, etc.

Delivery Time: 15-25 days

Payment Terms: L/C, T/T

Supply Ability: 10000 tons/year

Application: Oil And Gas Industry, Water Supply And Plumbing, Structural And Construction

Ends Type: Plain End, Beveled End, Threaded

Wall Thickness: 1.8mm-22.2mm

Outer Diameter: 21.3mm-660mm

Length: 5.8m-12m

Product Types: High-Frequency Welded Steel Pipe, Submerged-Arc Welded Steel Pipe, Electrogas Welded Steel Pipe

Support and Services:

At our company, we are committed to ensuring the highest level of satisfaction with our ERW Steel Pipe products. Our product technical support and services are designed to provide comprehensive assistance for all technical inquiries, issues, and needs related to our ERW Steel Pipes.

Our services include:

- Installation Guidance: Expert advice on the correct installation procedures to ensure optimal performance and safety of the ERW Steel Pipes.

- Troubleshooting Assistance: Rapid response to any operational problems, providing step-by-step solutions to resolve issues efficiently.

- Maintenance Tips: Detailed maintenance recommendations to prolong the lifespan of the ERW Steel Pipes and maintain their structural integrity.

- Product Specifications: Detailed technical specifications and documentation to support engineering and project planning.

- Quality Assurance: Information on our quality control processes and certifications to assure you of our commitment to quality.

- Upgrade Information: Updates on the latest improvements, enhancements, and product modifications.

Our technical support team is comprised of knowledgeable professionals who are well-versed in every aspect of ERW Steel Pipe technology. They are available to assist you with any technical queries or challenges you may encounter. We strive to provide timely and effective support to ensure that our products meet your expectations and requirements.

For any technical support related to our ERW Steel Pipe products, please reach out to us through the appropriate customer service channels. We are here to assist you with any questions or support you may need throughout the lifecycle of our products.

Packing and Shipping:

The ERW Steel Pipe is meticulously packed to ensure protection during transit. Each pipe is uniformly coated with a layer of protective oil to prevent rust and corrosion. Pipes are then individually wrapped with waterproof material, and the ends are capped with plastic protectors to safeguard against impact and debris. The wrapped pipes are carefully arranged and firmly secured in durable wooden crates or steel racks, tailored to the pipe dimensions to prevent movement and potential damage. The packaging is clearly labeled with handling instructions, product details, and a barcode for easy tracking. Finally, the crates or racks are loaded onto pallets and prepared for shipping, ensuring that the product arrives at its destination in pristine condition.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!