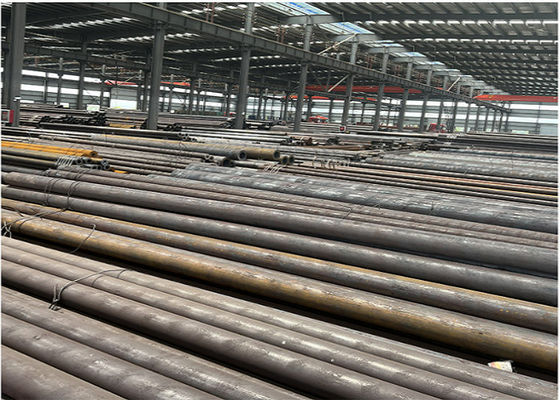

Product Description:

The production process of the Seamless Steel Pipe includes Hot Rolled, Cold Drawn, Cold Rolled, and Hot Extrusion. Hot Rolled pipes are made by heating the steel above its recrystallization temperature and then passing it through rollers to achieve the desired shape. Cold Drawn pipes are made by pulling the steel through a die to achieve the desired shape. Cold Rolled pipes are made by rolling the steel at room temperature to achieve the desired shape. Hot Extrusion pipes are made by forcing the steel through a die at high temperatures to achieve the desired shape.

The Seamless Steel Pipe is available in various standards such as ASTM A106, ASTM A53, API 5L, DIN 17175, GB/T8162, and GB/T8163. These standards specify the dimensions, physical properties, and chemical composition of the pipes. The ASTM A106 standard covers seamless carbon steel pipes for high-temperature service, while the ASTM A53 standard covers seamless and welded black and hot-dipped galvanized steel pipes. The API 5L standard covers seamless and welded steel pipes for pipeline transportation systems in the petroleum and natural gas industries.

The Seamless Steel Pipe is also available in different tolerances such as ±5% and ±10%. Tolerance refers to the allowable deviation from the specified dimensions of the pipe. The tolerance level depends on the application and the intended use of the pipe. A higher tolerance level is required for applications that require high precision and accuracy.

The Seamless Steel Pipe comes in various steel thicknesses ranging from 0.2mm to 100mm. The thickness of the pipe depends on the application and the intended use. A thicker pipe is required for applications that require high pressure and temperature resistance.

One of the key advantages of the Seamless Steel Pipe is that it can be cut to any length as per the customer's request. This makes it easier to transport and install the pipe. The Seamless Steel Pipe is also available in different finishes such as galvanized steel pipes. Galvanized pipes are coated with a layer of zinc to protect the steel from corrosion and rust.

In summary, the Seamless Steel Pipe (SS Pipe) is a type of pipe made from solid steel that does not have any seams or welding joints. It is available in various standards, tolerances, and steel thicknesses. The Seamless Steel Pipe can be cut to any length as per the customer's request and is also available in different finishes such as galvanized steel pipes.

Features:

- Product Name: Seamless Steel Pipe (sst pipe, steel tube, ss pipe)

- Surface Treatment:

- Black Painting

- Varnish Coating

- Anti-rust Oil

- Hot Galvanized

- 3PE, Etc.

- Tolerance: ±5%, ±10%

- Standard:

- ASTM A106

- ASTM A53

- API 5L

- DIN 17175

- GB/T8162

- GB/T8163

- Steel Thickness: 0.2-100mm

- Color: As Request

Technical Parameters:

| Technical Parameter | Description |

|---|

| Processing Service | Punching, Cutting, Bending |

| Surface Treatment | Black Painting, Varnish Coating, Anti-rust Oil, Hot Galvanized, 3PE, Etc. |

| Tolerance | ±5%, ±10% |

| Service | Cutting Any Length As Request |

| Production Process | Hot Rolled, Cold Drawn, Cold Rolled, Hot Extrusion |

| Packing | In Bundles, Seaworthy Wooden Cases, Steel Framed Cases, Or As Required |

| Steel Thickness | 0.2-100mm |

| Standard | ASTM A106, ASTM A53, API 5L, DIN 17175, GB/T8162, GB/T8163 |

| Color | As Request |

These technical parameters are for the Seamless Steel Pipe product, which can be used in a variety of applications, including extrusion aluminum profile, erw pipe, and galvanized steel pipes.

Applications:

The Seamless Steel Pipe is suitable for various applications, including:

- Oil and gas transportation

- Fluid transportation

- Boiler and heat exchanger

- Mechanical processing

- Structural use

The product is available in different packaging options, including plastic plugs in both ends, hexagonal bundles of max. 2,000kg with several steel strips, two tags on each bundle, wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, and plastic caps. It has a short delivery time of 5-7 working days and is available for payment through T/T or L/C. The Seamless Steel Pipe has a supply ability of 10000 tons/year, making it a reliable choice for customers who need a large quantity.

The Seamless Steel Pipe has undergone different production processes, including hot rolled, cold drawn, cold rolled, and hot extrusion, guaranteeing its high-quality performance. It adheres to various standards, including ASTM A106, ASTM A53, API 5L, DIN 17175, GB/T8162, and GB/T8163, making it a versatile and widely applicable product. The product is available for cutting any length as requested, ensuring that it meets the specific needs of the customer.

The Seamless Steel Pipe is available in different surface treatments, including black painting, varnish coating, anti-rust oil, hot galvanized, 3PE, etc. This makes it a versatile product for various applications. Whether it is for oil and gas transportation, fluid transportation, or mechanical processing, the Seamless Steel Pipe is a reliable and durable option that is worth considering.

In summary, the Seamless Steel Pipe is a high-quality product that is suitable for various applications. It is available in different packaging options, adheres to various standards, and is available for cutting any length as requested. It has a short delivery time, making it a reliable option for customers who need it urgently. The product is available in different surface treatments, ensuring that it meets the specific needs of the customer. Whether it is for oil and gas transportation, fluid transportation, or mechanical processing, the Seamless Steel Pipe is a versatile and reliable option that is worth considering.

Customization:

Customize your Seamless Steel Pipe with our product customization services:

- Brand Name: Seamless Steel Pipe

- Place of Origin: China

- Certification: BV, SGS, ABS

- Minimum Order Quantity: 1TON

- Price: USD600-1500/TON

- Packaging Details: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

- Delivery Time: 5-7 working days

- Payment Terms: T/T, L/C

- Supply Ability: 10000 tons/year

- Steel Thickness: 0.2-100mm

- Processing Service: Punching, Cutting, Bending

- Production Process: Hot Rolled, Cold Drawn, Cold Rolled, Hot Extrusion

- Surface Treatment: Black Painting, Varnish Coating, Anti-rust Oil, Hot Galvanized, 3PE, Etc.

- Standard: ASTM A106, ASTM A53, API 5L, DIN 17175, GB/T8162, GB/T8163

Our services allow you to customize your ss pipe according to your specifications. We offer processing services such as punching, cutting, and bending. Our production process includes hot rolled, cold drawn, cold rolled, and hot extrusion. We also offer surface treatments such as black painting, varnish coating, anti-rust oil, hot galvanized, 3PE, etc.

With a minimum order quantity of 1 ton, our Seamless Steel Pipe product is perfect for any project. We also offer extrusion aluminum profile and sst pipe options to meet your needs.

Support and Services:

Our Seamless Steel Pipe product comes with comprehensive technical support and services to ensure the efficient and effective use of the product. Our technical support team is available to answer any questions and offer guidance on installation, maintenance, and troubleshooting. We also provide services such as inspection and testing, product certification, and customization to meet specific requirements. Our goal is to provide our customers with a seamless experience in using our Seamless Steel Pipe product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!