Product Description:

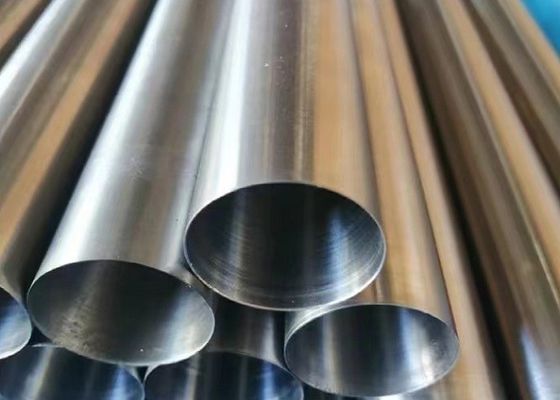

The Alloy Steel Tube is available in a range of wall thicknesses, from 1.2mm to 30mm, making it highly versatile and suitable for a wide range of applications. The tube is made of alloy steel, which means that it is highly resistant to corrosion and wear. The tube is designed to be used in high-temperature and high-pressure environments, making it ideal for use in applications such as heat exchangers, boilers, and other industrial processes.

The Alloy Steel Tube is an alloy steel tube that is designed for use in high-temperature and high-pressure environments. It is made of alloy steel, which gives it excellent resistance to corrosion and wear. The tube is available in a range of shapes and sizes, making it highly versatile and suitable for a wide range of applications. The tube is designed to be used in applications such as heat exchangers, boilers, and other industrial processes.

The Alloy Steel Tube is available in a range of surface treatments, including brightness and acid pickling. These surface treatments help to protect the tube from corrosion and wear, making it highly durable and long-lasting. The tube is designed to be used in high-temperature and high-pressure environments, which means that it is ideal for use in applications such as heat exchangers, boilers, and other industrial processes.

The Alloy Steel Tube is a highly versatile and durable product that is designed for use in a wide range of industrial applications. It is made of alloy steel, which gives it excellent resistance to corrosion and wear. The tube is available in a range of shapes and sizes, making it suitable for use in a wide range of applications. The tube is designed to be used in applications such as heat exchangers, boilers, and other industrial processes.

In summary, the Alloy Steel Tube is a highly versatile and durable product that is designed for use in a wide range of industrial applications. It is an alloy steel tube that is available in a range of wall thicknesses and surface treatments, making it suitable for use in a wide range of applications. The tube is designed to be used in high-temperature and high-pressure environments, making it ideal for use in applications such as heat exchangers, boilers, and other industrial processes.

Features:

- Product Name: Alloy Steel Tube

- Material: Alloy Steel

- Alloy Or Not: Alloy

- Shape: Tube

- Wall Thickness: 1.2-30

- Surface Treatment: Brightness, Acid Pickling

This product can also be referred to as Alloy Steel Pressure Tube, Alloy Steel Tubing, or Alloy Steel Pressure Tubing.

Technical Parameters:

| Product Name |

Alloy Steel Tube |

| Length |

Customized |

| Wall Thickness |

1.2-30 |

| Surface Treatment |

Brightness, Acid Pickling |

| Material |

Alloy Steel |

| Shape |

Tube |

| Alloy Or Not |

Alloy |

This Alloy Steel Tube is an essential component of the Alloy Steel Tubular System and is often used as an Alloy Steel Heat Exchanger Tube.

Applications:

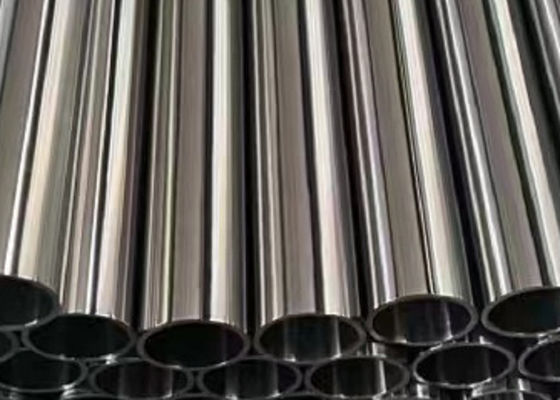

The Alloy Steel Tube is a highly versatile product that can be used in a variety of applications. Its primary use is in the construction of Alloy Steel Tubular Systems. These systems are used in a variety of industries, including oil and gas, chemical processing, power generation, and more. The Alloy Steel Tube is also commonly used in the construction of Alloy Steel Pressure Tubes and Alloy Steel Boiler Tubes. These tubes are used to transport fluids under high pressure and high temperature conditions and must be able to withstand the rigors of these harsh environments.

The JOHO Alloy Steel Tube is available in a range of customized lengths to suit the needs of your specific application. The product is also available with a surface treatment of Brightness or Acid Pickling to further enhance its durability and resistance to corrosion. The Alloy Steel Tube is made from high-quality materials and is designed to provide long-lasting performance even in the most demanding environments.

Overall, the JOHO Alloy Steel Tube is an excellent choice for a wide range of applications. Whether you are building an Alloy Steel Tubular System, Alloy Steel Pressure Tube, or Alloy Steel Boiler Tube, this product is sure to meet your needs and exceed your expectations.

Customization:

- Brand Name: JOHO

- Place of Origin: CHINA

- Certification: ISO 9001

- Minimum Order Quantity: 1 TON

- Packaging Details: Woodencase/Woven bag

- Delivery Time: within 40 days

- Payment Terms: LC,TT,ect,.

- Surface Treatment: Brightness, Acid Pickling

- Length: Customized

- Shape: Tube

- Alloy Or Not: Alloy

- Wall Thickness: 1.2-30

Our Alloy Steel Tube can be customized to be used as an Alloy Steel Cylinder, Alloy Steel Line Pipe, or Alloy Steel Pipe. Contact us today to learn more about how we can customize our Alloy Steel Tube to meet your specific needs.

Packing and Shipping:

Product Packaging:

- The alloy steel tubes will be packaged in wooden crates or bundles with plastic wrapping.

- The crates/bundles will be securely fastened with steel bands and labeled with product information.

Shipping:

- The alloy steel tubes will be shipped via standard freight methods such as sea or rail.

- Shipping costs will be calculated based on the weight and destination of the order.

- Customers are responsible for any additional customs fees or taxes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!