Product Description:

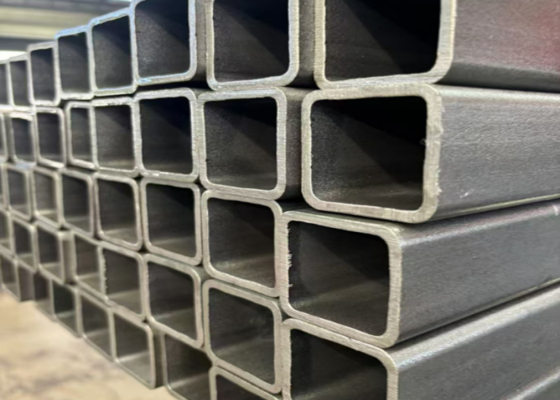

Steel Hollow Sections are a versatile and essential product in the construction and industrial sectors. These tubular steel sections are designed to offer strength, durability, and structural integrity for a wide range of applications.

The Steel Hollow Sections undergo rigorous testing and inspection processes to ensure high quality and reliability. These include Hydraulic Test, Eddy Current Testing, Infrared Test, and Third Party Inspection to meet industry standards and specifications.

When it comes to packaging, Steel Hollow Sections are meticulously protected to prevent damage during transportation and storage. The product is carefully packed in Wooden Crates, Steel Frames, and End Cap Protection to maintain its quality and shape.

Steel Hollow Sections find extensive application in various industries due to their structural strength and versatility. They are commonly used as Fluid Pipes, Drill Pipes, and Structural Pipes in construction, manufacturing, and infrastructure projects.

The surface finish of Steel Hollow Sections can vary based on requirements. They are available in Black, Color, Varnish, and Galvanized Coating finishes to suit different environmental conditions and aesthetic preferences.

With a range of shapes available, Steel Hollow Sections offer flexibility in design and construction. The product comes in Square, Rectangular, and Round shapes, allowing for precise fitting and seamless integration into different structures.

Features:

- Product Name: Steel Hollow Sections

- Application:

- Fluid Pipe

- Drill Pipe

- Structure Pipe

- Processing Service:

- Bending

- Welding

- Decoiling

- Punching

- Cutting

- Test & Inspection:

- With Hydraulic Test

- Eddy Current

- Infrared Test

- The Third Party Inspection

- Package:

- Wooden Crate Packaging

- Steel Frame Packaging

- End Cap Protection

- Shape:

Technical Parameters:

| Parameter |

Options |

| Package |

Wooden Crate Packaging, Steel Frame Packaging, End Cap Protection |

| Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

| Surface |

Black, Color, Varnish, Galvanized Coating |

| Application |

Fluid Pipe, Drill Pipe, Structure Pipe |

| Grade |

ASTM A500, S235JR, S235JOH, S355JR, S355JOH, C250LO, C350LO, SS400, Q195, Q235, Q345 |

| Shape |

Square, Rectangular, Round |

| Test & Inspection |

With Hydraulic Test, Eddy Current, Infrared Test, The Third Party Inspection |

Applications:

Steel Hollow Sections are versatile products that find numerous application occasions and scenarios across various industries due to their exceptional attributes. Originating from China, these hollow sections come with a range of certifications including ISO 9001, ISO 14001, CE, API, ASTM, and EN, ensuring top-notch quality and compliance with international standards.

These Steel Hollow Sections are ideal for constructing tubular steel structures, offering strength and durability to the overall framework. Their use in creating steel tubular structures is prominent in industries such as construction, infrastructure development, automotive, and manufacturing.

The minimum order quantity for Steel Hollow Sections is 1 ton, making it accessible for both small and large-scale projects. With a price range of USD600-2300 per ton, these hollow sections provide cost-effective solutions for various applications.

When it comes to packaging, Steel Hollow Sections are securely packed using protective materials, customized crating, securing and bracing techniques, clear labeling for easy identification, moisture protection to prevent corrosion, and comprehensive documentation and manuals for reference.

With a delivery time of 10-25 working days, customers can rely on timely shipments to meet project deadlines. Payment terms include T/T and L/C, offering flexibility and convenience in transactions.

With a supply ability of 10000 tons per year, Steel Hollow Sections ensure consistent availability to meet market demands. These sections can undergo processing services such as bending, welding, decoiling, punching, and cutting, providing tailored solutions for specific project requirements.

Available in grades such as ASTM A500, S235JR, S235JOH, S355JR, S355JOH, C250LO, C350LO, SS400, Q195, Q235, and Q345, Steel Hollow Sections cater to a wide range of structural needs.

Test and inspection procedures for these sections include hydraulic testing, eddy current testing, infrared testing, and third-party inspections, guaranteeing quality and reliability. The surface finish options include black, color-coated, varnished, and galvanized coatings, enhancing both aesthetics and corrosion resistance.

Overall, Steel Hollow Sections are essential components for building sturdy and efficient steel structures, offering a combination of strength, versatility, and quality assurance.

Customization:

Product Customization Services for Steel Hollow Sections:

Brand Name: Steel Hollow Sections

Place of Origin: China

Certification: ISO 9001, ISO 14001, CE, API, ASTM, EN

Minimum Order Quantity: 1 TON

Price: USD600-2300/TON

Packaging Details: Protective Materials, Customized Crating, Securing and Bracing, Clear Labeling, Moisture Protection, Documentation and Manuals

Delivery Time: 10-25 working days

Payment Terms: T/T, L/C

Supply Ability: 10000 tons/year

Test & Inspection: With Hydraulic Test, Eddy Current, Infrared Test, The Third Party Inspection

Package: Wooden Crate Packaging, Steel Frame Packaging, End Cap Protection

Application: Fluid Pipe, Drill Pipe, Structure Pipe

Grade: ASTM A500, S235JR, S235JOH, S355JR, S355JOH, C250LO, C350LO, SS400, Q195, Q235, Q345

Processing Service: Bending, Welding, Decoiling, Punching, Cutting

Support and Services:

Our Steel Hollow Sections product line offers comprehensive technical support and services to ensure the optimal performance and longevity of your structures. Our team of experts is available to provide guidance on product selection, installation best practices, and troubleshooting assistance.

Additionally, we offer a range of services including on-site inspections, maintenance recommendations, and customized solutions to meet your specific project requirements. Our commitment to customer satisfaction extends to our post-purchase support, where we are dedicated to addressing any issues or concerns promptly and effectively.

Packing and Shipping:

Product Packaging:

The Steel Hollow Sections are carefully packaged in bundles or as per customer requirements to ensure safe transportation and handling. Each section is securely wrapped and protected to prevent damage during transit.

Shipping:

Once packaged, the Steel Hollow Sections are loaded onto pallets or into containers for shipment. We work with reliable shipping partners to ensure timely delivery to the designated destination. Customers can also opt for specific shipping methods or provide their preferred logistics arrangements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!