Product Description:

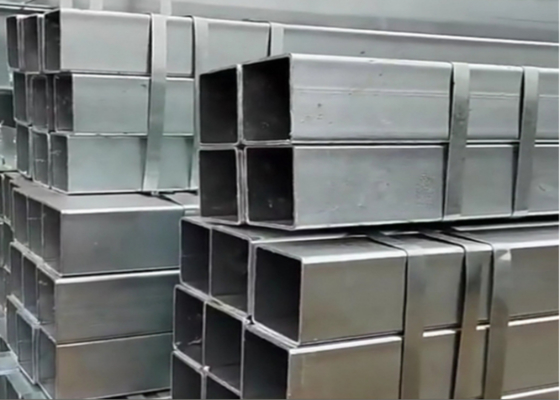

Steel Hollow Sections are tubular steel profiles that are widely used in various industries such as construction, machinery, automotive, furniture, and more. These steel tubular profiles are known for their versatility, strength, and durability, making them a popular choice for a wide range of applications.

Manufactured using the hot rolled technique, Steel Hollow Sections are produced to meet the highest quality standards. The material grade used for these profiles ranges from Q195 to Q235, ensuring excellent performance and reliability in different structural applications.

When it comes to tolerance, Steel Hollow Sections typically have a tolerance of ±10%, which ensures precision and consistency in their dimensions. This level of tolerance is crucial in construction and other industries where accuracy is paramount.

One of the key features of Steel Hollow Sections is their invoicing by theoretical weight. This means that customers are billed based on the calculated weight of the steel profiles, providing transparency and accuracy in transactions.

Steel Hollow Sections play a vital role in the construction industry, where they are used in the creation of tubular steel structures such as beams, columns, and trusses. These structures provide strength and stability to buildings, bridges, and other infrastructure projects, making them essential components in modern construction.

In the machinery and automotive sectors, Steel Hollow Sections are utilized for various applications such as frame construction, chassis components, and support structures. Their high strength-to-weight ratio makes them ideal for reducing overall weight while maintaining structural integrity.

Additionally, Steel Hollow Sections find extensive use in the furniture industry for creating durable and aesthetically pleasing designs. From chair frames to table legs, these tubular steel profiles offer a perfect blend of strength and style, enhancing the quality and longevity of furniture pieces.

In conclusion, Steel Hollow Sections are versatile, reliable, and high-quality tubular steel profiles that find wide-ranging applications in construction, machinery, automotive, furniture, and more. With their hot rolled technique, Q195-235 grade, ±10% tolerance, and invoicing by theoretical weight, these steel tubular profiles are essential components in various industries, contributing to the strength and durability of structures and products worldwide.

Features:

- Product Name: Steel Hollow Sections

- Craft:

- Hollow Section

- Hot Roll

- Cold Roll

- Usage:

- Construction Structure

- Furniture

- Processing Service:

- Section Shape: Square

- Application: Construction, Machinery, Automotive, Furniture, Etc.

Technical Parameters:

| Processing Service |

Welding, Cutting |

| Surface Treatment |

Black, Galvanized, Painted, Or Oiled |

| Surface |

Customers' Requirement |

| Usage |

Construction Structure, Furniture |

| Section Shape |

Square |

| Tolerance |

±10% |

| Invoicing |

By Theoretical Weight |

| Thickness Range |

0.5mm To 25mm |

| Grade |

Q195-235 |

| Craft |

Hollow Section, Hot Roll, Cold Roll |

Applications:

Steel Hollow Sections are versatile products that find application in a wide range of scenarios due to their durability, strength, and adaptability. Originating from China, these hollow sections are ideal for constructing various steel tubular structures and tubular steel structures in different industries and settings.

With certifications such as ISO 9001, ISO 14001, CE, API, ASTM, and EN, customers can trust the quality and reliability of Steel Hollow Sections. The minimum order quantity of 1 ton makes these products accessible for both small-scale and large-scale projects.

The price range of USD600-2300 per ton offers competitive pricing for high-quality steel products. When it comes to packaging, Steel Hollow Sections are carefully protected with customized crating, securing and bracing, clear labeling, moisture protection, and comprehensive documentation and manuals.

Delivery time for Steel Hollow Sections ranges from 10 to 25 working days, ensuring timely supply for project requirements. Flexible payment terms such as T/T and L/C make transactions convenient for customers.

With a supply ability of 10000 tons per year, Steel Hollow Sections are readily available to meet demand. The tolerance level of ±10% ensures consistency in product dimensions.

These sections come in a thickness range of 0.5mm to 25mm, catering to a variety of structural requirements. The surface treatment options include black, galvanized, painted, or oiled finishes, providing both protection and aesthetic appeal.

Whether used in construction, infrastructure, manufacturing, or other industries, Steel Hollow Sections offer a reliable solution for creating robust and stable steel structures. Their square section shape further enhances their versatility for different design applications.

Customization:

Product Customization Services for Steel Hollow Sections:

Brand Name: Steel Hollow Sections

Place of Origin: China

Certification: ISO 9001, ISO 14001, CE, API, ASTM, EN

Minimum Order Quantity: 1 TON

Price: USD600-2300/TON

Packaging Details: Protective Materials, Customized Crating, Securing and Bracing, Clear Labeling, Moisture Protection, Documentation and Manuals

Delivery Time: 10-25 working days

Payment Terms: T/T, L/C

Supply Ability: 10000 tons/year

Processing Service: Welding, Cutting

Section Shape: Square

Packing: In Bundles Or According To Customer's Requirements

Surface: Customers' Requirement

Grade: Q195-235

Support and Services:

Our Product Technical Support and Services for Steel Hollow Sections include:

- Expert guidance on product selection based on your specific project requirements.

- Assistance with design considerations and structural calculations.

- Recommendations for proper installation and maintenance procedures.

- Troubleshooting support for any issues that may arise during or after installation.

Packing and Shipping:

Product Packaging for Steel Hollow Sections:

The steel hollow sections are carefully packed in bundles to ensure safe transportation. Each bundle is securely strapped and labeled with product details for easy identification.

Shipping Information:

Once the steel hollow sections are packed, they are loaded onto pallets or into containers for shipping. The packages are then shipped via trucks, trains, or ships to reach their destination safely and on time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!