Product Description:

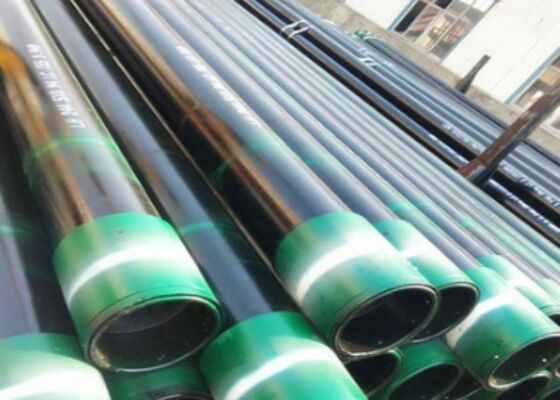

The Steel Casing Pipe is a robust and versatile product designed primarily for water transport applications. Manufactured from high-quality steel, this pipe offers exceptional strength, durability, and resistance to various environmental factors, making it an ideal choice for infrastructure projects requiring reliable water conveyance solutions. The product is commonly referred to as a Carbon Steel Casing Tube, emphasizing its composition and structural integrity.

The Steel Casing Pipe features a wide range of thickness options, ranging from 2.11mm to an impressive 300mm. This extensive thickness range allows for customization based on the specific requirements of different projects, whether they demand lightweight solutions or heavy-duty protection. Such versatility ensures that the Carbon Steel Casing Tube can be utilized in diverse settings, from residential water supply lines to large-scale industrial water transport systems.

With an outer diameter spanning from 21.3mm to 1420mm, the Steel Casing Pipe accommodates various piping layouts and system designs. This diameter range provides engineers and planners with the flexibility to select the appropriate pipe size that matches flow capacity, pressure, and spatial constraints. The broad spectrum of sizes further highlights the adaptability of the Carbon Steel Casing Tube in both small and large projects.

Material quality is paramount in ensuring the longevity and performance of water transport pipes, and the Steel Casing Pipe excels in this regard. Made from premium-grade steel, the Carbon Steel Casing Tube is engineered to withstand mechanical stresses, corrosion, and environmental wear. This makes it highly suitable for underground installation where soil conditions and moisture can pose significant challenges. The steel composition also allows for excellent weldability and machining, facilitating easier installation and maintenance.

Surface treatment options for the Steel Casing Pipe are comprehensive, offering multiple layers of protection and aesthetic finishes. Customers can choose from bare steel for basic applications or opt for advanced coatings such as black painting, anti-corrosion coating, 3PE (three-layer polyethylene), FBE (fusion bonded epoxy), epoxy coating, galvanized finish, and varnish. Each of these treatments serves a specific purpose, enhancing the pipe’s resistance to rust, chemical exposure, and abrasion. The availability of these coatings ensures that the Carbon Steel Casing Tube remains durable and functional in a variety of environmental conditions.

In water transport systems, the integrity of the piping infrastructure is critical to prevent leaks, contamination, and system failures. The Steel Casing Pipe delivers on these requirements by providing a sturdy and corrosion-resistant conduit for water flow. Its robust construction minimizes the risk of damage during installation and operation, thereby reducing maintenance costs and extending the service life of the entire water transport network.

Moreover, the Carbon Steel Casing Tube is a cost-effective solution due to its combination of strength, longevity, and ease of installation. The range of thicknesses and diameters available allows for optimized material usage, ensuring that projects can be tailored to budget without compromising quality. Additionally, the variety of surface treatments offers options to meet specific environmental challenges, further enhancing the value proposition of this product.

In summary, the Steel Casing Pipe stands out as an essential component in water transport infrastructure. Its extensive thickness range from 2.11mm to 300mm, wide outer diameter options from 21.3mm to 1420mm, and high-grade steel construction make it a reliable and adaptable choice for various applications. The multiple surface treatment options, including bare, black painting, anti-corrosion coating, 3PE, FBE, epoxy coating, galvanized, and varnish, ensure longevity and protection against harsh conditions. Known widely as the Carbon Steel Casing Tube, this product combines strength, durability, and versatility, making it an indispensable element in the construction and maintenance of efficient water transport systems.

Features:

- Product Name: Steel Casing Pipe

- Packing: In Bundles, In Loose, Plastic End Caps Or According To Customers' Requirements

- Thickness: 2.11mm~300mm

- Base Pipe Material: API5CT N80 L80 P110

- Mold: Customer Required

- Use: For Water Transport

- High-quality Carbon Steel Casing Tube for durable performance

- Reliable Carbon Steel Casing Tube designed to meet industry standards

- Versatile Carbon Steel Casing Tube suitable for various applications

Technical Parameters:

| Outer Diameter |

21.3 - 1420 MM |

| Mold |

Customer Required |

| Special Pipe |

API Pipe |

| Base Pipe Material |

API5CT N80 L80 P110 |

| Surface Treatment |

Bare, Black Painting, Anti-corrosion Coating, 3PE, FBE, Epoxy Coating, Galvanized, Varnish |

| Material |

Steel |

| End Connection |

Male/female Threaded |

| Use |

For Water Transport |

| Thickness |

2.11mm~300mm |

| NDT |

ET, HT, RT, PT |

This Carbon Steel Casing Tube is designed with high-quality materials and advanced surface treatments to ensure durability and performance. The Carbon Steel Casing Tube meets the required standards with customizable mold options and reliable end connections. Our Carbon Steel Casing Tube is ideal for water transport applications, offering a wide range of diameters and thicknesses to suit customer needs.

Applications:

The JOHO Steel Casing Pipe, originating from China and certified by ISO, SGS, and BV, is an exceptional choice for various industrial applications. This Carbon Steel Casing Tube is designed primarily for water transport, making it ideal for projects that require durable and reliable piping solutions. With an outer diameter range from 21.3 mm to 1420 mm and thickness varying between 2.11 mm to 300 mm, this Carbon Steel Casing Tube can accommodate a wide range of engineering needs, from small-scale water supply systems to large infrastructure pipelines.

One of the main application occasions for the JOHO Steel Casing Pipe is in municipal water distribution systems. Its sturdy construction and corrosion resistance make it perfect for underground water pipelines, ensuring long-lasting performance even in harsh environments. The male/female threaded end connections facilitate easy installation and maintenance, which is crucial for urban infrastructure projects that demand quick turnaround times and high reliability.

In addition to municipal water transport, this Carbon Steel Casing Tube is widely utilized in agricultural irrigation systems. Farmers and agricultural engineers rely on JOHO’s steel casing pipes to deliver water efficiently to fields, enhancing crop yields and optimizing water usage. Its robust design withstands varying pressures and environmental conditions, making it a dependable choice for irrigation networks.

Industrial facilities also benefit from JOHO Steel Casing Pipes in their water intake and discharge systems. Whether it’s for cooling processes or wastewater management, the durable carbon steel construction ensures resistance to mechanical damage and chemical exposure. The availability of non-destructive testing (NDT) methods such as ET, HT, RT, and PT further guarantees the quality and safety of each pipe used in critical applications.

JOHO offers flexible packaging options tailored to customer requests and ensures delivery within 40 days, with a minimum order quantity of just 1 ton. Payment terms include L/C and T/T, making the procurement process smooth and convenient. Whether for new construction or replacement projects, the Carbon Steel Casing Tube from JOHO stands out as a reliable and efficient solution for water transport across various sectors.

Customization:

JOHO offers premium Carbon Steel Casing Tube products made from high-quality steel materials, specifically designed for water transport applications. Our Carbon Steel Casing Tube is manufactured using base pipe materials such as API5CT N80, L80, and P110, ensuring durability and reliability.

Originating from China, our Carbon Steel Casing Tube is certified by ISO, SGS, and BV, guaranteeing compliance with international quality standards. We provide comprehensive NDT services including ET, HT, RT, and PT to ensure the integrity and performance of every casing pipe.

We accept minimum order quantities starting from 1 TON, with packaging tailored to customer requests. Delivery is assured within 40 days, and payment terms are flexible, including L/C and T/T options.

With thickness options ranging from 2.11mm to 300mm, JOHO's Carbon Steel Casing Tube can be customized to meet specific project requirements, making it an ideal choice for a variety of industrial applications.

Support and Services:

Our Steel Casing Pipe product is designed to provide exceptional strength and durability for a wide range of applications including construction, infrastructure, and oil & gas industries. To ensure optimal performance and longevity, we offer comprehensive technical support and services.

Our technical support team is available to assist with product selection, installation guidance, and troubleshooting. We provide detailed specifications, engineering support, and customized solutions tailored to your project requirements.

We also offer on-site inspection services, quality assurance testing, and maintenance advice to help you maximize the efficiency and lifespan of your steel casing pipes. Additionally, we provide training sessions and technical documentation to empower your team with the necessary knowledge for proper handling and usage.

By choosing our Steel Casing Pipe, you gain access to a dedicated support network committed to ensuring your project's success from start to finish.

Packing and Shipping:

Our Steel Casing Pipes are carefully packaged to ensure maximum protection during transportation and handling. Each pipe is coated with anti-rust oil and wrapped in a protective plastic film to prevent corrosion and surface damage. Pipes are bundled securely with steel straps and wooden supports to maintain stability and prevent movement within the shipment.

For shipping, the Steel Casing Pipes are loaded onto pallets or directly into containers, depending on the order size and destination. We use heavy-duty lifting equipment and follow strict loading protocols to avoid any deformation or damage. Our logistics team coordinates with reliable carriers to ensure timely and safe delivery to the customer’s specified location.

Additionally, all shipments include detailed documentation such as packing lists, certificates of compliance, and quality inspection reports to facilitate smooth customs clearance and customer verification.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!