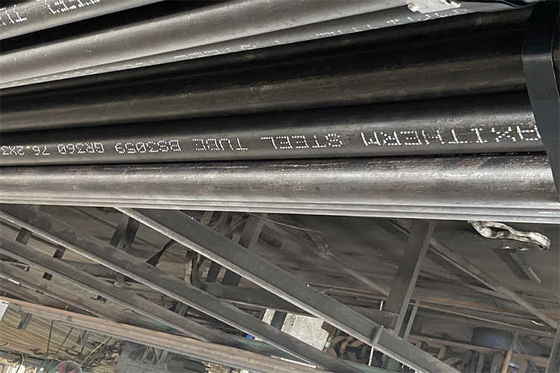

Customizable Length Heat Exchanger Tube For Efficient Heat Transfer

Product Description:

Superior Material: Our boiler tubes are constructed from high-grade steel alloys, carefully picked for their remarkable strength, heat tolerance and corrosion resistance. This provides for long-term effectiveness and dependability in hostile operating conditions.

Precise Dimensions: Each and every boiler tube is created with exact measurements and accurate tolerances to ensure a proper and seamless fit into your boiler system. This promotes efficient heat conduction while reducing energy waste, ultimately enlarging the system's overall efficiency.

Enhanced Surface Treatment: The surface of our boiler tubes goes through thorough processes like cleaning, descaling, passivating, and covering. These procedures advance rust resistance, counter scale creation and improve total durability.

Secure Connections: The ends of our boiler tubes are treated with extreme care to guarantee a tight fit and correct sealing. Through cutting, facing, beveling, deburring, chamfering, and examining methods, we can guarantee secure and leak-proof joint connectivity with other parts of the boiler.

Features:

High Temperature Resistance: Boiler tubes are able to withstand incredibly hot temperatures generated in boiler systems, allowing for efficient heat transfer whilst preventing any kind of structural deformation or failure.

Pressure Resistance: Boiler tubes are designed with a great deal of strength and integrity, providing resistance to the high pressures that are typically found in boiler systems. As such, they are able to safely contain pressurized fluids or gasses, contributing to safe and reliable operation.

Corrosion Resistance: Boiler tubes are constructed out of materials that can resist corrosion, and thereby also fend off the corrosive effects of flue gases, chemicals, and water found in boiler systems. This resistance allows for an extended lifespan and upheld performance.

Efficient Heat Transfer: Boiler tubes are given smooth surfaces and tight dimensions to ensure enhanced heat transfer from combustion gases to the water or steam within the boiler. Such levels of efficiency are advantageous in terms of energy efficiency, fuel consumption, and performance of the system as a whole.

Precise Dimensions: Boiler tubes must have dimensions with tight tolerances, facilitating secure connections and smooth flow of liquids or gasses. This ensures optimal performance from the boiler system.

Technical Parameters:

Boiler Tubes

Boiler tubes are usually made from high-quality steel alloys, such as carbon steel, low alloy steel, or stainless steel. The exact material composition may differ depending on the application and operating conditions.

The outer diameter (OD) of boiler tubes is the exact measurement of the tube's outer circumference. This ensures the proper fitment and compatibility with other boiler components.

The wall thickness of boiler tubes is the measurement of the tube's wall from the inner surface to the outer surface. It contributes to the tube's strength, pressure resistance, and heat transfer efficiency.

The length of boiler tubes is the measurement of the tube from one end to the other. It can be adjusted according to the specific requirements of the boiler system or installation.

Applications:

Power Generation

Boiler tubes play a critical role in power plants, contributing to the efficient transfer of heat from combustion gases to water or steam that drives turbines to produce power. This process allows electricity to be generated.

Industrial Boilers

Boiler tubes are used in various industrial boilers, from those in manufacturing and chemical processing to those in oil refineries and food processing. The tubes help to ensure efficient fuel combustion and the production of steam or hot water for industrial processes.

Heat Exchangers

Boiler tubes are also used in heat exchangers to transfer heat between two fluids without mixing them. This process is beneficial in HVAC systems, refrigeration units, and other industries where efficient heat transfer is needed.

Petrochemical Industry

The petrochemical industry relies on boiler tubes for processes involving high temperatures and pressure. They are commonly used in steam cracking units, reformers, and other equipment where resistant to corrosive environments is paramount.

Support and Services:

Heat Exchanger Steel Tube Technical Support and Service

Our Heat Exchanger Steel Tube is designed to provide reliable, effective and cost-efficient operation in a wide variety of applications. Our team of experienced professionals is available to provide technical support and service to ensure the highest level of performance and reliability.

Technical Support

- Expert consultation and advice

- Troubleshooting and problem solving

- Software and hardware upgrades

- Operating system and application support

- Real-time system monitoring

Service

- Installation and maintenance

- Emergency response and repair

- Regular inspections and preventive maintenance

- Replacement parts and components

- On-site and remote support

Packing and Shipping:

Packaging and Shipping for Heat Exchanger Steel Tube

Heat Exchanger Steel Tube is packaged in standard cartons, wrapped in plastic film, and then shipped in standard containers. Each package is labeled in English, indicating the product name, model number, quantity, origin, and contact information of the manufacturer. All products will be shipped within the specified delivery time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!