Standard Manufactured Seamless Boiler Tubes Accepted Customized Requirements

Product Description:

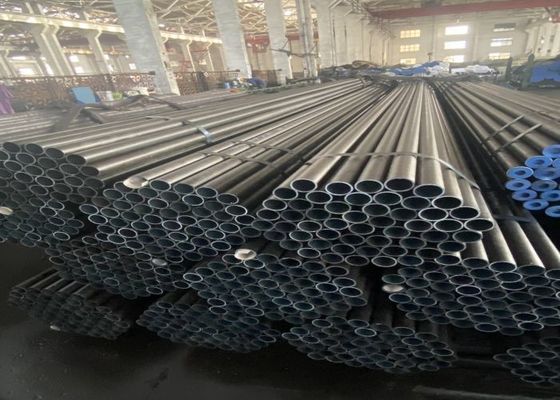

Our boiler tubes are crafted from high-grade steel alloys, carefully selected for their superior strength, heat resistance, and corrosion resistance properties. This guarantees long-lasting performance and reliability in challenging operating environments.

Each boiler tube is crafted with exact dimensions and tight tolerances to boost heat transfer efficiency and reduce energy wastage, thus improving the system's overall performance.

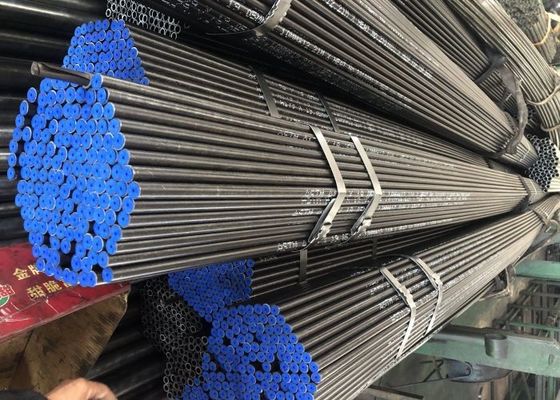

The surface of our boiler tubes undergo thorough treatments such as cleaning, passivation, descaling, and coating. This increases corrosion resistance, eliminates scale formation, and amplifies the tubes' durability.

The ends of our boiler tubes are crafted with precise care to guarantee secure connections and leak-free seals. Our advanced cutting, facing, beveling, deburring, chamfering, and inspection processes guarantee such results.

Features:

| Characteristic |

Description |

| Seamless |

Made without any welded joints, providing superior strength |

| Material |

Typically made from carbon steel, alloy steel, or stainless steel |

| High Temperature |

Designed to withstand high temperatures and pressure |

| Corrosion Resistance |

Resistant to corrosion and oxidation |

| Precision Dimension |

Manufactured with precise outer and inner diameters |

| Smooth Internal Surface |

Provides efficient heat transfer and reduced pressure drop |

| High Strength |

Offers high tensile and yield strength |

| Wide Range of Sizes |

Available in various diameters and wall thicknesses |

| Industry Standards |

Comply with relevant industry standards and specifications |

| Applications |

Used in boilers, power plants, heat exchangers, and more |

Technical Parameters:

| Technical Parameter |

Description |

| Material |

Carbon steel, alloy steel, stainless steel, or other alloys |

| Outer Diameter (OD) |

Range: 3.175 mm to 609.6 mm |

| Wall Thickness |

Range: 1 mm to 15 mm |

| Length |

Customizable, typically in meters |

| Heat Treatment |

Normalized, annealed, or as per customer requirements |

| Tolerance |

As per applicable standards or customer specifications |

| Surface Finish |

Pickled and passivated, oiled, or as per customer specifications |

| Testing and Inspection |

Non-destructive testing (e.g., ultrasonic, eddy current), dimensional inspection, visual inspection |

| Standards |

ASTM, ASME, DIN, EN, JIS, and other industry standards |

| Certification |

Mill test certificate (MTC) provided upon request |

Applications:

Power Generation

Boiler tubes are indispensable in power plants for generating electricity. They are essential for transferring heat from combustion gases to water or steam to power turbines. This process is required for electricity production.

Industrial Boilers

Boiler tubes play a crucial role in various industrial boilers, including those used in manufacturing, chemical processing, and food production. These tubes ensure effective combustion of fuels and generation of steam or hot water for industrial use.

Heat Exchangers

Boiler tubes are also employed in heat exchangers for transferring heat between two fluids without mixing. This is mainly used in HVAC systems, refrigeration units, and process industries for efficient heat transfer.

Petrochemical Industry

These tubes are extensively utilized in petrochemical processes, which involve high temperatures and pressure. These can be seen in steam cracking units, reformers, and similar equipment to ensure reliable heat transfer and resistance to harsh conditions.

Inspections and tests performed:

Chemical Composition Inspection, Mechanical Properties Test (Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), Surfce and Dimension Test, Non-destructive Test, Hydrostatic Test.

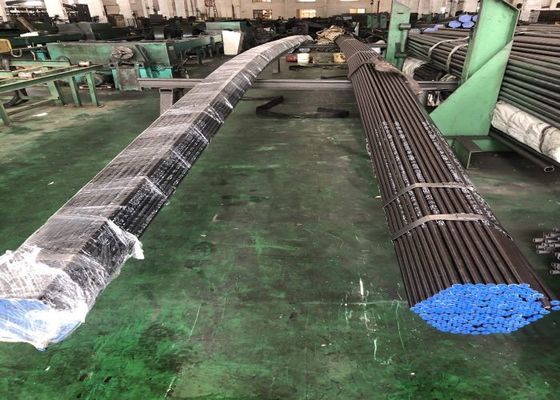

Packing and Shipping:

Packaging and Shipping of Heat Exchanger Steel Tube

Heat exchanger steel tubes are usually packaged in bundles of various sizes, depending on the size of the tubes. Each bundle is individually labeled and securely packaged to protect the tubes from any potential damage.

Heat exchanger steel tubes are shipped by sea, air or land. Depending on the destination, the method of shipping will vary. All shipments are properly insured and tracked to ensure a safe and timely delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!