Product Description:

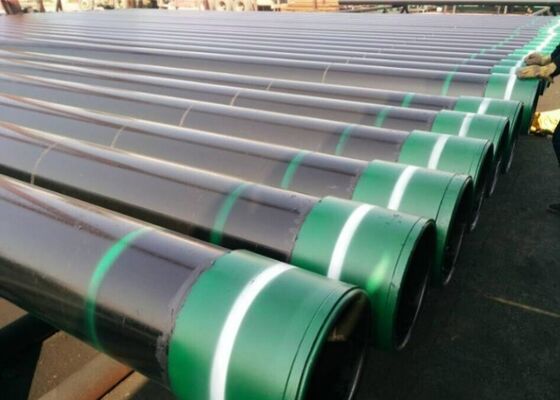

The Steel Casing Pipe is a high-quality product designed specifically for demanding applications such as water transport. Manufactured using premium base pipe materials including API5CT N80, L80, and P110 grades, this product ensures exceptional strength, durability, and resistance to corrosion. The use of these high-grade materials guarantees that the casing pipe can withstand harsh environments and provide long-lasting performance in various industrial settings.

One of the key features of this Steel Casing Pipe is its end connection design, which utilizes male/female threaded ends. This type of connection allows for easy and secure assembly, ensuring leak-proof joints that are critical for maintaining the integrity of water transport systems. The threaded connection also simplifies installation and maintenance, reducing downtime and operational costs for users.

The Steel Casing Pipe is versatile in terms of packaging options. It can be packed in bundles or in loose form depending on the customer's requirements. Additionally, plastic end caps are used to protect the pipe ends during transportation and handling, preventing damage and contamination. This flexibility in packing ensures that the product reaches its destination in optimal condition, ready for immediate use.

Customization is another important aspect of this product. The mold of the Steel Casing Pipe can be tailored according to customer specifications, allowing for a wide range of sizes and shapes to meet specific project needs. This adaptability makes it an ideal choice for various applications where standard dimensions may not suffice. Customers can rely on the manufacturer’s expertise to deliver precisely engineered casing tubes that fit perfectly into their systems.

At the core of this product’s functionality is the Carbon Steel Casing Tube, a crucial component that provides structural support and protection. The Carbon Steel Casing Tube is known for its robustness and ability to withstand high pressure and environmental stress. This makes it particularly suitable for water transport applications, where maintaining the integrity of pipelines is essential to prevent leaks and ensure efficient flow.

Moreover, the Carbon Steel Casing Tube used in this Steel Casing Pipe offers excellent resistance to wear and mechanical damage. Its high tensile strength and toughness enable it to perform reliably even under extreme conditions. Whether the application involves underground water pipelines or surface-level transport systems, the Carbon Steel Casing Tube ensures consistent performance and longevity.

In addition to its mechanical properties, the Carbon Steel Casing Tube also provides excellent resistance to corrosion, which is a common challenge in water transport systems. The combination of advanced material grades such as API5CT N80, L80, and P110 enhances the pipe’s ability to resist rust and chemical degradation. This results in reduced maintenance requirements and extended service life, making the Steel Casing Pipe a cost-effective solution for water transport infrastructure.

Overall, the Steel Casing Pipe featuring the Carbon Steel Casing Tube is a reliable and efficient choice for water transport applications. Its superior material composition, customizable mold options, and secure male/female threaded end connections make it a standout product in the piping industry. Whether used in municipal water supply systems, irrigation projects, or industrial water transport, this casing pipe delivers outstanding performance and durability.

Customers looking for a robust and adaptable piping solution will find the Steel Casing Pipe to be an excellent investment. With its combination of high-grade carbon steel materials, flexible packaging options, and tailored mold designs, it meets the highest standards of quality and functionality. Trust the Carbon Steel Casing Tube-based Steel Casing Pipe to provide dependable service and contribute to the success of your water transport projects.

Features:

- Product Name: Steel Casing Pipe

- Material: Carbon Steel Casing Tube

- Outer Diameter Range: 21.3 - 1420 MM

- Base Pipe Material: API5CT N80, L80, P110

- Special Pipe Type: API Pipe

- Surface Treatment Options:

- Bare

- Black Painting

- Anti-corrosion Coating

- 3PE

- FBE

- Epoxy Coating

- Galvanized

- Varnish

- Designed as a high-quality Carbon Steel Casing Tube for durability and performance

- Reliable Carbon Steel Casing Tube suitable for various industrial applications

Technical Parameters:

| Material |

Steel |

| Use |

For Water Transport |

| End Connection |

Male/female Threaded |

| Outer Diameter |

21.3 - 1420 MM |

| NDT |

ET, HT, RT, PT |

| Base Pipe Material |

API5CT N80 L80 P110 |

| Mold |

Customer Required |

| Surface Treatment |

Bare, Black Painting, Anti-corrosion Coating, 3PE, FBE, Epoxy Coating, Galvanized, Varnish |

| Special Pipe |

API Pipe |

| Packing |

In Bundles, In Loose, Plastic End Caps Or According To Customers' Requirements |

Applications:

The JOHO Steel Casing Pipe, originating from China and certified by ISO, SGS, and BV, is an exceptional product designed to meet various industrial needs. Manufactured using high-quality base pipe materials such as API5CT N80, L80, and P110, this Carbon Steel Casing Tube offers outstanding durability and strength, making it ideal for demanding applications. With a wide outer diameter range from 21.3 to 1420 mm, JOHO’s Carbon Steel Casing Tube can be tailored to fit diverse project specifications, ensuring versatility across numerous industries.

This Carbon Steel Casing Tube finds extensive use in oil and gas drilling operations where reliable casing pipes are crucial for well integrity and safety. It is frequently employed in the construction of boreholes, protecting the well structure from collapse and preventing contamination of underground resources. Additionally, the steel casing pipes serve critical roles in water well drilling, geothermal energy extraction, and mining activities. Their robust construction and superior surface treatments—ranging from bare and black painting to advanced anti-corrosion coatings like 3PE, FBE, epoxy coating, galvanized, and varnish—enhance resistance to harsh environmental conditions, extending service life in aggressive surroundings.

JOHO Steel Casing Pipes are packaged according to customer requirements, whether bundled, loose, or with plastic end caps, ensuring safe transportation and easy handling. The delivery time is efficiently managed within 40 days, with flexible payment terms such as L/C and T/T to accommodate various business needs. With a minimum order quantity of 1 ton, customers can procure these Carbon Steel Casing Tubes in quantities suited to both small-scale and large-scale projects. Custom mold options further enable tailored solutions for specialized applications.

In infrastructure development, this Carbon Steel Casing Tube is used in pipeline construction, underground utility protection, and structural reinforcement. Its adaptability makes it a preferred choice for engineers and contractors who demand reliability and performance. Whether applied in oil fields, water wells, or industrial construction, JOHO’s Steel Casing Pipes deliver consistent quality and long-lasting results, backed by comprehensive certifications and rigorous quality control.

Customization:

JOHO offers comprehensive product customization services for Carbon Steel Casing Tube, ensuring that each steel casing pipe meets your specific requirements. Manufactured in China, our Carbon Steel Casing Tube comes with internationally recognized certifications including ISO, SGS, and BV, guaranteeing quality and reliability.

We accept a minimum order quantity of 1 TON, providing flexibility for both small and large scale projects. Packaging details are tailored as per customer requests to ensure safe and efficient delivery. Our delivery time is within 40 days, allowing you to plan your operations with confidence.

Payment terms are convenient and secure, supporting L/C and T/T options. The material used in our Carbon Steel Casing Tube is high-quality steel, with various surface treatment options available such as bare, black painting, anti-corrosion coating, 3PE, FBE, epoxy coating, galvanized, and varnish to suit different environmental and operational needs.

The outer diameter of the Carbon Steel Casing Tube ranges from 21.3 MM to 1420 MM, accommodating a wide range of applications. Non-destructive testing (NDT) methods including ET, HT, RT, and PT are performed to ensure the integrity and performance of each tube. Additionally, molds can be customized according to customer requirements to provide a perfect fit for your project.

Choose JOHO for your Carbon Steel Casing Tube needs and benefit from expert customization services that combine quality, flexibility, and timely delivery.

Support and Services:

Our Steel Casing Pipe product is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide detailed product documentation, including specifications, installation guidelines, and maintenance instructions to assist you throughout the product lifecycle.

Our experienced technical support team is available to offer expert advice on product selection, application, and troubleshooting. We also provide on-site support and inspection services to ensure proper installation and adherence to quality standards.

In addition, we offer customized solutions tailored to specific project requirements, including special sizes, coatings, and material grades. Our commitment to quality and service excellence ensures that you receive reliable and durable steel casing pipes for your projects.

Regular training sessions and webinars are conducted to keep customers informed about the latest industry practices and product innovations. We strive to build long-term partnerships by delivering exceptional support and value-added services.

Packing and Shipping:

The Steel Casing Pipe is carefully packaged to ensure maximum protection during transportation and handling. Each pipe is coated with a protective layer to prevent rust and corrosion. The pipes are bundled securely with steel straps and placed on sturdy wooden pallets to maintain stability and prevent damage.

For shipping, the Steel Casing Pipes are loaded using appropriate lifting equipment to avoid any deformation or impact damage. The bundles are then covered with waterproof tarpaulins to protect against moisture and environmental elements during transit. We ensure that all shipments comply with international shipping standards to guarantee safe delivery to the destination.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!