Product Description:

Our Stainless Steel Pipe Tubing product line offers an extensive range of high-quality pipes designed to meet the diverse needs of various industries. Manufactured with precision and adhering to stringent quality standards, these pipes are ideal for applications that demand durability, corrosion resistance, and superior mechanical properties. Whether you require stainless steel welded pipe, stainless steel rectangular pipe, or stainless steel structural pipe, our product portfolio ensures optimal performance and reliability.

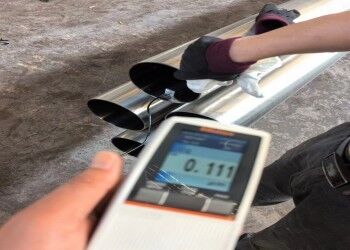

The surface finish of our stainless steel pipe tubing is available in multiple options, including BA (Bright Annealed), 2B, NO.1, NO.3, and NO.4 finishes. These finishes are carefully applied to enhance both the aesthetic appeal and functional attributes of the pipes. BA and 2B finishes provide a smooth, reflective surface suitable for applications where appearance is important, while NO.1, NO.3, and NO.4 finishes offer varying degrees of roughness and texture to meet specific industrial requirements. This variety ensures that customers can select the perfect surface finish to match their project specifications.

Our stainless steel pipe tubing is manufactured in compliance with a comprehensive range of international standards, including ASTM A312, ASTM A269, ASTM A213, ASTM A249, ASTM A270, ASTM A554, ASTM A778, ASTM A789, ASTM A790, DIN 17456, DIN 17458, JIS G3459, JIS G3463, EN 10216, EN 10217, and more. These standards guarantee that every pipe meets rigorous criteria for dimensions, mechanical properties, chemical composition, and overall quality. This broad coverage of standards makes our tubing products suitable for global markets and various industrial sectors.

Our stainless steel pipes are available in a wide array of grades to accommodate the specific needs of different applications. The grades we offer include 301L, 301, 304N, 310S, 410, 316Ti, 316L, 316, 321, 410S, 410L, 430, 309S, 304, 439, 425M, 409L, 904L, and 317L. Each grade provides unique properties such as enhanced corrosion resistance, heat resistance, or mechanical strength. For example, grade 316L is highly resistant to corrosion and ideal for chemical processing, while 310S offers excellent high-temperature resistance. This extensive range allows customers to select the most suitable material for their specific operating conditions.

One of the key highlights of our product line is the versatility in dimensions, particularly the thickness range, which spans from as thin as 0.3mm up to a robust 150mm. This wide thickness range ensures that the stainless steel pipe tubing can be utilized in applications ranging from delicate instrumentation lines to heavy-duty structural support systems. Additionally, the available shapes include round pipes, stainless steel rectangular pipes, and other structural pipe profiles, catering to diverse engineering and architectural requirements.

Packaging is another critical aspect we prioritize to ensure the safe delivery of our stainless steel pipe tubing. Our products are carefully packed in bundles, wooden cases, pallets, or other customized packaging solutions depending on the customer’s needs. This attention to detail in packaging safeguards the pipes from damage during transit and storage, preserving their quality until they reach the end-user.

Whether you are searching for stainless steel welded pipe for fluid transport, stainless steel rectangular pipe for framing and architectural purposes, or stainless steel structural pipe for construction and industrial frameworks, our product line delivers exceptional strength, precision, and longevity. With rigorous quality control, adherence to international standards, a broad selection of grades and finishes, and flexible packaging options, our stainless steel pipe tubing is a reliable choice for engineers, fabricators, and contractors worldwide.

In conclusion, our Stainless Steel Pipe Tubing offers unmatched versatility, quality, and performance. Backed by comprehensive standard certifications and a diverse range of grades and finishes, these pipes are engineered to excel in demanding environments. Whether for industrial, commercial, or structural applications, our stainless steel welded pipe, rectangular pipe, and structural pipe solutions provide the durability and reliability essential for your projects’ success.

Features:

-

Product Name: Stainless Steel Pipe Tubing

-

Size Range: 1/4 Inch - 48 Inch

-

Ends Available: Plain, Beveled, Threaded

-

Shape Options: Round, Square, Rectangle

-

Packing Methods: Bundles, Wooden Cases, Pallets, Etc.

-

Surface Finish: BA, 2B, NO.1, NO.3, NO.4

-

Includes stainless steel rectangular pipe for versatile applications

-

High-quality stainless steel tubular products designed for durability

-

Available as stainless seamless steel pipe for superior strength and corrosion resistance

Technical Parameters:

|

Ends

|

Plain, Beveled, Threaded

|

|

Packing

|

Bundles, Wooden Cases, Pallets, Etc.

|

|

Features

|

High Temperature Resistance, Corrosion Resistance, High Strength, Good Formability, Good Weldability, Etc.

|

|

Surface Finish

|

BA/2B/NO.1/NO.3/NO.4

|

|

Size

|

1/4 Inch - 48 Inch

|

|

Technique

|

Cold Rolled, Hot Rolled

|

|

Length

|

2000mm, 2500mm, 3000mm, 6000mm, 12000mm

|

|

Grade

|

301L, 301, 304N, 310S, 410, 316Ti, 316L, 316, 321, 410S, 410L, 430, 309S, 304, 439, 425M, 409L, 904L, 317L

|

|

Processing Service

|

Bending, Welding, Punching, Cutting, Moulding

|

|

Thickness

|

0.3mm - 150mm

|

Applications:

The Stainless Steel Pipe Tubing offered by Stainless Steel Pipe, a reputable brand originating from China, is a versatile and high-quality product designed to meet diverse industrial and commercial needs. Certified by ISO, SGS, and BV, this tubing ensures exceptional reliability and performance. With a minimum order quantity of 1 TON and customized packaging options available as per customer requests, it caters to both small and large-scale projects efficiently. The delivery time of 10-15 working days and flexible payment terms including L/C and T/T make it convenient for global buyers.

These stainless seamless steel pipes are manufactured following stringent standards such as ASTM A312, ASTM A269, ASTM A213, ASTM A249, ASTM A270, ASTM A554, ASTM A778, ASTM A789, ASTM A790, DIN 17456, DIN 17458, JIS G3459, JIS G3463, EN 10216, and EN 10217, ensuring compatibility with international specifications. Available in thicknesses ranging from 0.3mm to 150mm and produced using advanced cold rolled and hot rolled techniques, these pipes demonstrate excellent strength, corrosion resistance, and durability.

The product comes in various shapes including round, square, and rectangle, offering flexibility to suit different structural and mechanical applications. Ends can be customized to plain, beveled, or threaded based on project requirements. This adaptability makes the stainless steel square tube and other shapes ideal for construction, automotive, aerospace, chemical, and food processing industries.

In construction, stainless seamless steel pipes and stainless steel square tubes are widely used for scaffolding, structural frameworks, and architectural designs due to their aesthetic appeal and resistance to weathering. In the automotive and aerospace sectors, these tubes contribute to manufacturing lightweight, strong, and corrosion-resistant components. The food and chemical industries rely on the hygienic and corrosion-resistant nature of these pipes for processing, transportation, and storage equipment.

Moreover, the stainless steel square tube is perfect for furniture manufacturing, offering both strength and a sleek finish for modern designs. Industrial machinery and equipment also benefit from the durability and precision of these pipes, making them indispensable in various engineering applications. Overall, the Stainless Steel Pipe Tubing from this Chinese brand provides a reliable solution for a multitude of application occasions and scenarios, combining quality, customization, and timely delivery.

Customization:

Our Stainless Steel Pipe Tubing products are fully customizable to meet your specific requirements. Manufactured under the trusted brand name "Stainless Steel Pipe" and originating from China, our products come with ISO, SGS, and BV certifications ensuring top quality and reliability. We accept a minimum order quantity of 1 TON, with packaging details tailored as per customer requests.

We offer a range of processing services including bending, welding, punching, cutting, and moulding to provide you with precisely crafted stainless steel tube and pipe solutions. Our delivery time is typically 10-15 working days, and we support flexible payment terms such as L/C and T/T for your convenience.

Choose from various shapes including round, square, and rectangle to suit your project needs. The pipe ends are available in plain, beveled, or threaded finishes. Surface finishes offered include BA, 2B, NO.1, NO.3, and NO.4, providing the perfect look and performance for stainless steel coil tubing and stainless steel rectangular pipe applications.

We supply a wide range of grades such as 301L, 301, 304N, 310S, 410, 316Ti, 316L, 316, 321, 410S, 410L, 430, 309S, 304, 439, 425M, 409L, 904L, and 317L, ensuring that you get the ideal material for durability and corrosion resistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!